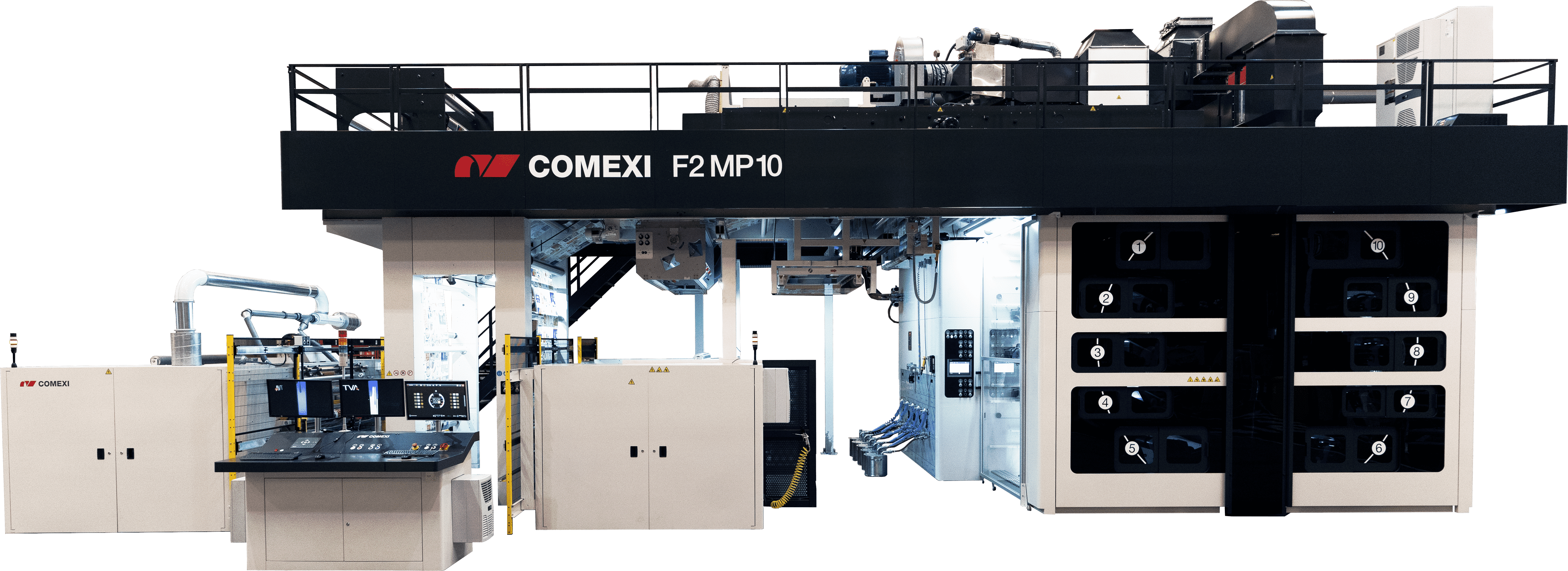

Flexographic Printing

Reflect the high quality of your products with our high-fidelity 10-color flexographic printing. Your flexible packaging will be printed by knowledgeable press operators who have an average of 15 years or more of experience in flexographic printing. We offer solvent-based inks and provide a wide range of capabilities and technology: 10-color central impression flexographic printing Reverse and surface printing up to 60″ wide Advanced plate mounting equipment with microdot system capability for accurate registration Inline defect detection system Overprint varnish “Gloss/Matte” Accurate bar code printing Sophisticated ink blending systems Accurate in-house custom color matching Spectro-densitometer color control

Environmentally Conscious Printing

We strive to protect our environment by recycling solvents and printing plates used in the printing process. Over 98 percent of volatile organic compounds are captured and destroyed using catalytic and regenerative thermal oxidizers.

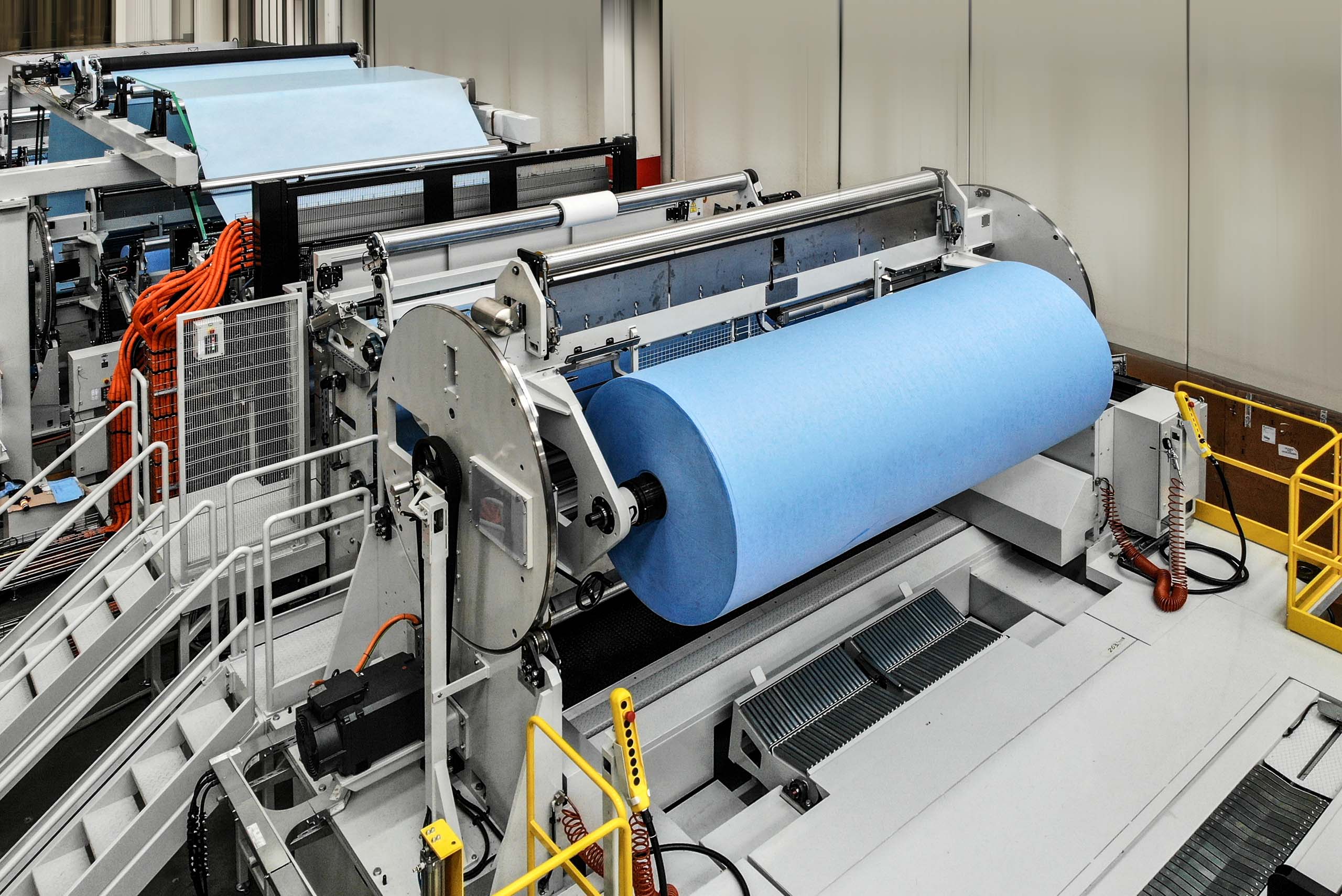

Custom Engineered Laminations

While some flexible packaging manufacturers offer a standard “menu” of flexible packaging materials, at New Wave Converting, Inc., we engineer customized flexible packaging structures designed specifically for your products. We’ve specialized in flexible packaging since 1980, and our expertise in polymer chemistry and flexible packaging engineering allows us to design optimal, cost-effective flexible packaging materials. We work with a vast range of films, foils, papers, and resins when engineering customized flexible packaging laminations. A flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in your packaging’s performance and presentation. Each layer provides specific performance characteristics:

- Oxygen, moisture, or light resistance

- Chemical resistance

- Puncture resistance

- Tear resistance

- Rigidity

- Glossy or matte appearance

- Opacity or translucency

- Heat seal ability

- Print receptivity

Based on your requirements (including regulatory, cost, and aesthetic requirements) packaging equipment, product formulation, projected life cycle, and distribution methods, we can custom-engineer and suggest optimal flexible packaging structures for each of your products.

Pouch Converting

In addition to our many years of experience in manufacturing flexible packaging laminations, we have a wide range of pouch converting equipment. Our versatile premade pouch converting equipment provides some of the most extensive in-house premade pouch converting capabilities in the industry. Since we aren’t forced to outsource pouch converting like some flexible packaging suppliers, we have full control of your pouches’ quality throughout the entire process – from pouch engineering to pouch converting. We manufacture custom-engineered premade pouches within tight deadlines.

Pouch Converting Capabilities:

- Stand up bottom gusseted K-seal pouches

- Stand up bottom gusseted Doyen pouches

- Press-to-close zipper pouches

- Slider pouches (exposed or hooded)

- Glanded pouches

- Pouches with die-cut handles

- Three-side seal pouches

- Side gusseted bottom seal pouches (quad seal)

- Side gusseted bottom seal pouches (back fin seal)